High Lead in Oil Samples…Bearing Wear?!

(And a sidebar about dealing with Knock)

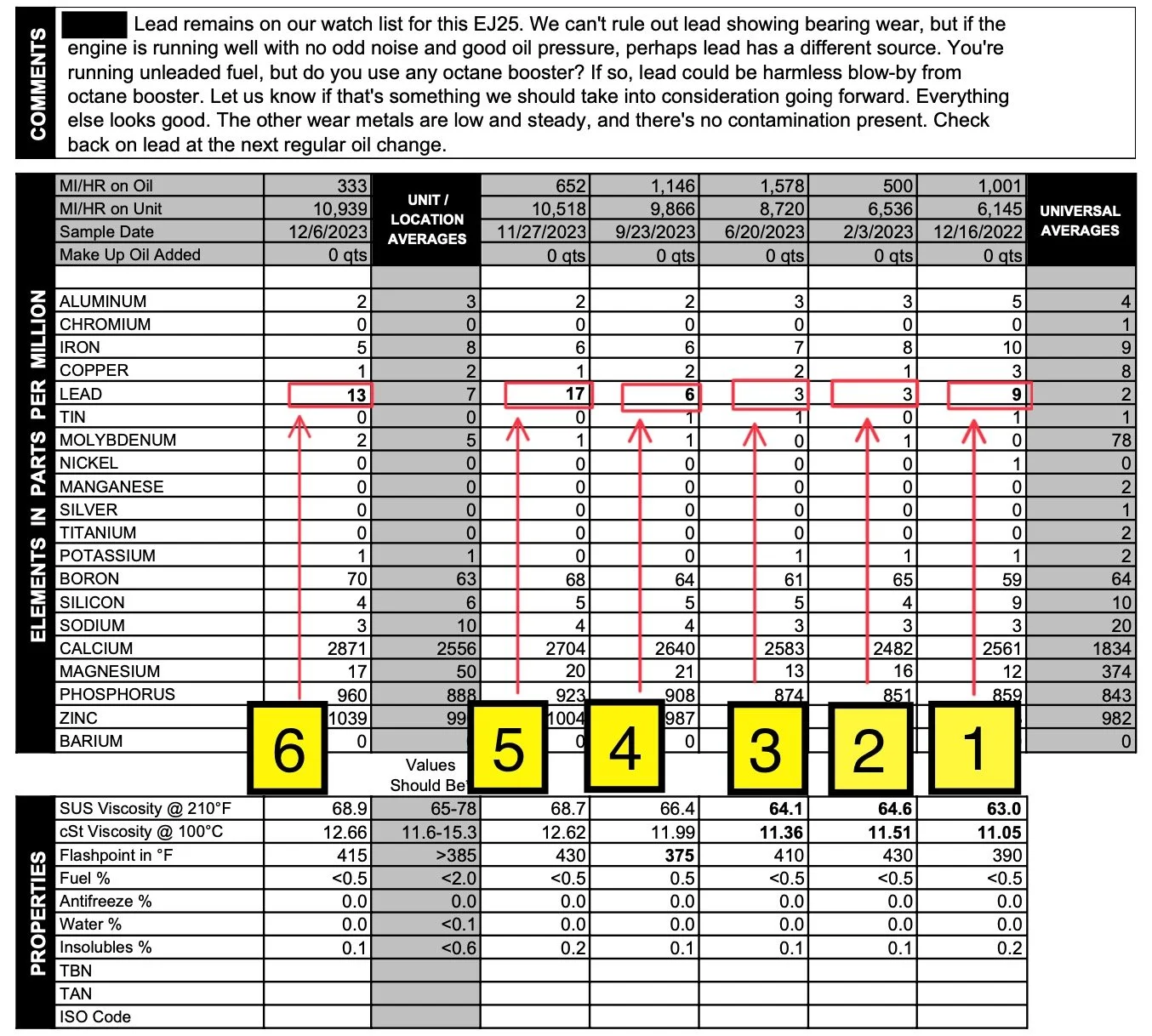

During a track day at Button Willow, my oil temperature reached around 270 F in the oil pan. The post-track oil sample exhibited elevated lead (#1), which I worried was a sign of accelerated bearing wear. This sent me into a long-term paranoia that I was on the verge of rod-bearing failure. I began fixating on every noise the motor made. EJ motors are pretty noisy, when you add forged internals there are plenty of noises that make your imagination run wild. This began a 15-month investigation to figure out just how worried I should be.

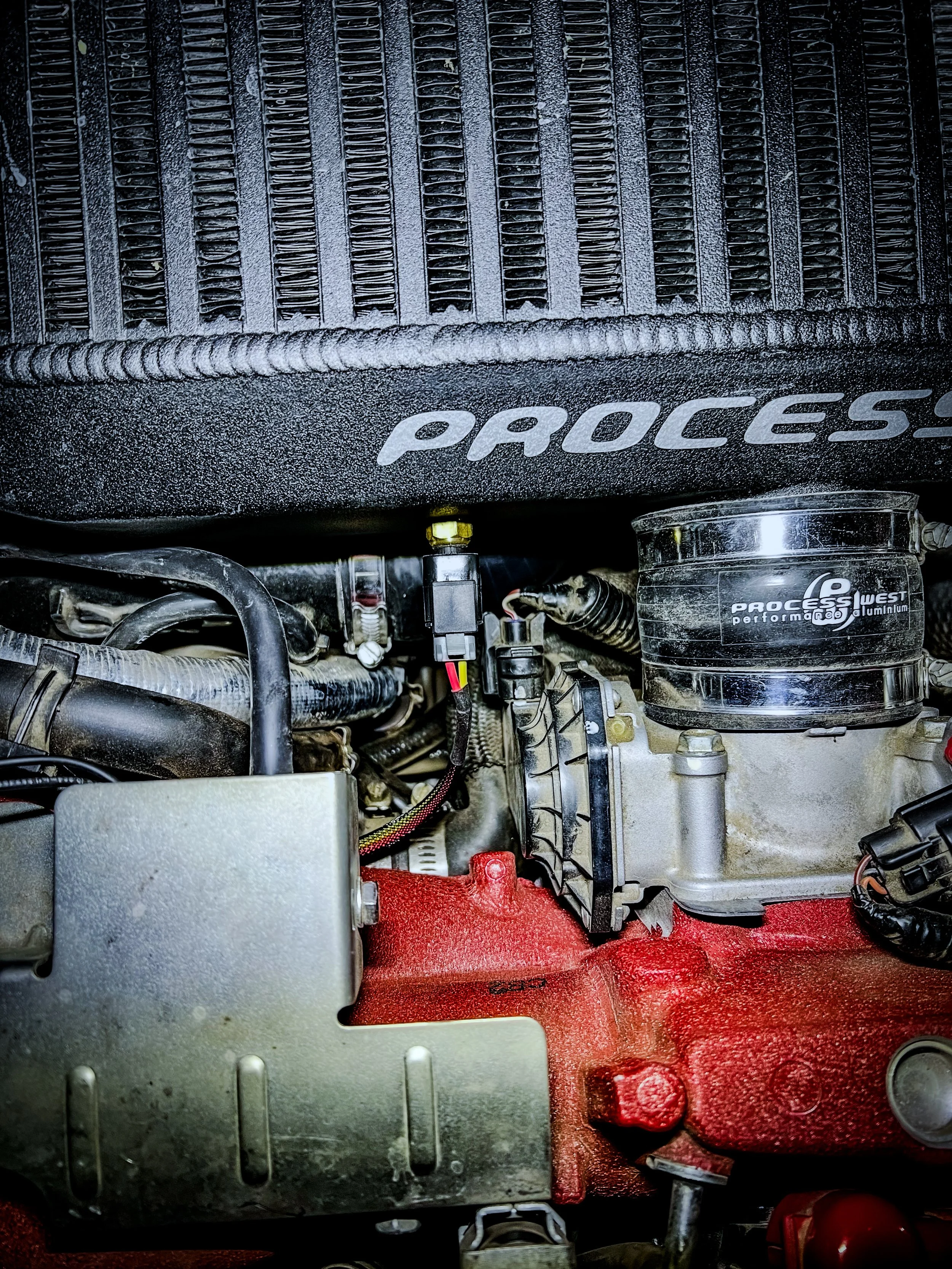

After the excessive oil temps and an elevated lead reading from my oil sample (#1), I installed a Process West oil cooler. The oil cooler kept my oil temperature under control on the next track day, and the next two oil samples showed a return to normal lead levels (#2, #3). I did start data logging after the original oil over temp track day and discovered a new issue. Although my oil samples came back good (#2, #3), my data logs showed I had significant knock on track. This became its own side adventure in diagnosing but has some important implications here.

…Wow, I was so wrong!…

After seeing some knock in my data logs under load during the track day in Feb 2023(#2), I devised what turned out to be a bad theory. My original tuner recommended running 1-2 gallons of 100 Octane on track days. I had followed his advice but still had knock under load. The earlier sessions of the day did not show any meaningful knock, but the later sessions saw the knock progressively worsen. I started the days on 91 Chevron pump gas and then would refill with VP Racing Fuel gas at the track (1-2 gallons of 100 octane and top off with 91 octane). VP Racing Fuel's website says that their fuels do not contain ethanol. I wondered if the 10% ethanol added to the regular street fuel was providing some kind of additional cooling/knock resistance early in the day. Then I hypothesized that as I continued to top off with the VP fuel, perhaps I was losing that protection and getting the knock. Wow, I was so wrong!

I was hoping that the lead issue was isolated to the excessive oil temps and things were under control; but that was not the case. In fall 2023, I moved across the country to the northeast. Obviously, my first priority was getting the car out on track, and Palmer Motorsport Park fit the bill. I took Paul’s advice and ran a healthy amount of 100 Octane and my data logs were clear of any knock. After my first track day at Palmer, my oil sample came back with 6 ppm of lead (#4). Not terrible, but I was concerned to see it on the rise again. I went back to Palmer the next month, and this time, the sample came back at 17 ppm(#5)! I contacted IAG with my oil samples to get their diagnosis. IAG was awesome and told me, based on my motor build, that as long as the oil pressure at warm idle was 20psi or greater and there weren’t any symptoms, then I shouldn’t have anything to worry about. So, the verdict was press on.

The next track day (#3), I only used 91 Chevron pump gas to test my theory. The morning sessions were uneventful. In an afternoon session, my car started knocking its block off! I had a -5.6 knock event under full load, and the DAM decreased to 0.5! So, NOT a fuel problem. It turns out that 91 pump gas with 10% ethanol is actually gas that has an octane rating below 91, and the 10% ethanol gets the octane rating up to 91. Which means 91 octane is even more trash than I thought.

My knock issue was caused by heat soaking as the ambient temperature rose over the course of the day. The VP fuel and 100 octane had been helping; if anything, I should have been running a lot more 100 octane. I later went to Yimisport, where Paul got me sorted out with a new tune and a temp sensor located in the intercooler outlet. This way, the car would proactively pull timing as it heat-soaked instead of waiting for the motor to knock before making an adjustment. He also emphasized that there isn’t a danger of running too much high octane on the motor and that I should run about half a tank of 100 octane while on the track. Getting back to the lead issue, you may have noticed that despite the knock issue during samples #2 and #3; the lead was back to normal levels.

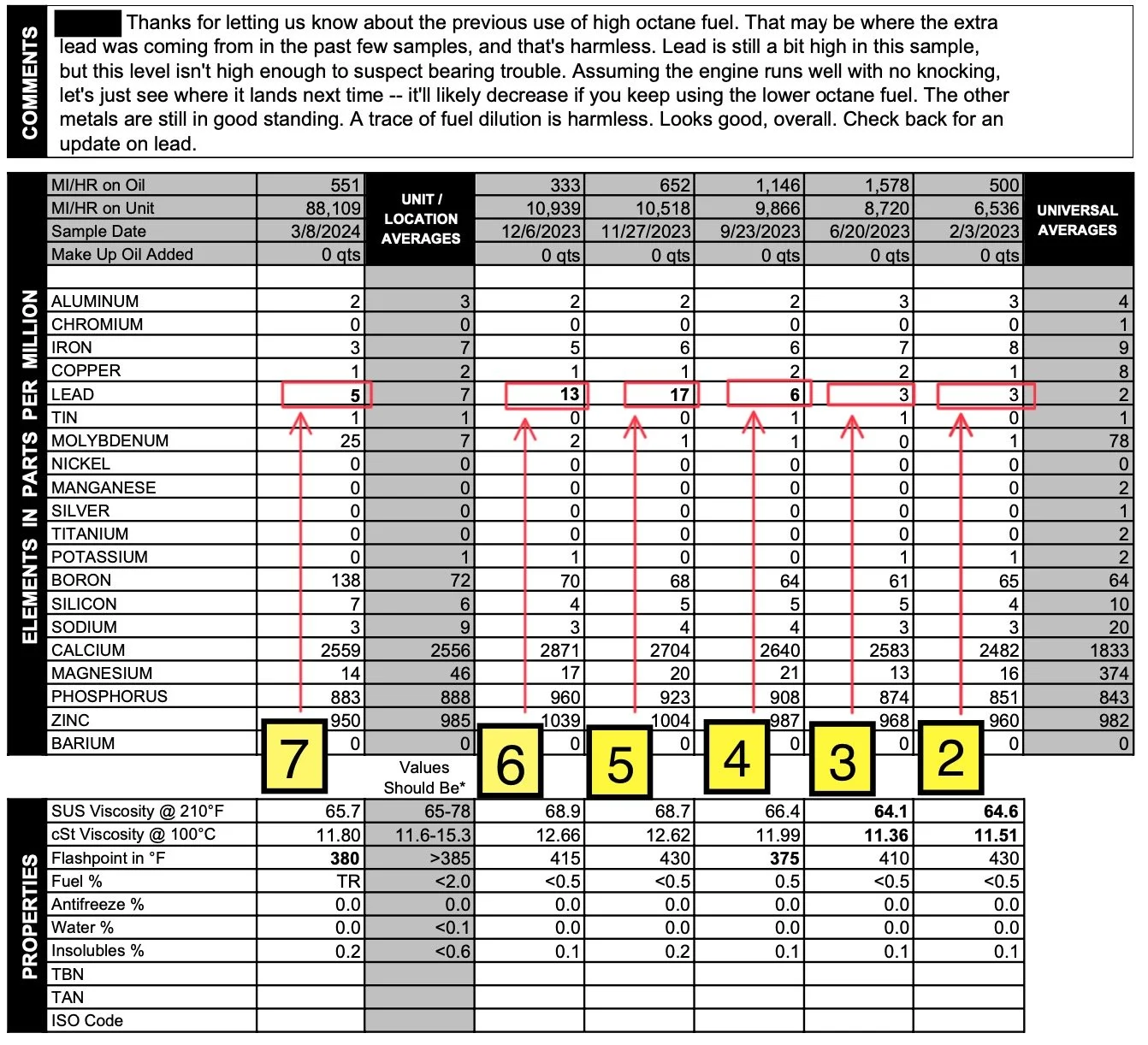

A new theory for the lead source came to mind…100-octane fuel. Blackstone often sees elevated lead in fuel samples that use Octane boosters or leaded fuel. The 100 Octane at the track is unleaded, so it seemed unlikely that this could be the culprit. Blackstone did not have enough data on gasoline motors running 100 Octane to say that the fuel was the culprit. However, under the good advice of Paul, I had been running more 100 Octane on these track days. I was, in fact, progressively running more 100 octane each track day, which correlated with the rising lead in my oil samples. Therefore, I continued on and went to another track day before the season ended. Again, it came back with high lead (13 ppm, #6). The next step was to take an oil sample without any track time or 100 Octane fuel on it and see if the lead level returned to normal levels.

I drove the car with fresh oil for a similar duration (500 miles) as the previous samples between track days. This sample had a small amount of leftover racing fuel in the tank mixed with 93 pump gas. Then I only ran 93 pump gas and street drove the car for 500 miles. The sample came back a 5ppm! Still not the 3 ppm that is expected, but as Blackstone points out, some residual lead can be expected in the fuel system. It seems that unleaded 100 octane racing fuel does have higher lead content than regular pump gas. Don’t be shocked if you have higher than normal lead levels in your samples after running race gas.

Here’s what I learned:

100 Octane is cheaper than a new motor

Running 100 Octane can cause lead ppm to increase in your oil samples

Oil samples are only useful if you do them regularly and compare results over time

Pump gas with 10% ethanol starts as a lower octane fuel than advertised, and the ethanol raises the octane level to the advertised amount

Data log, data log, data log

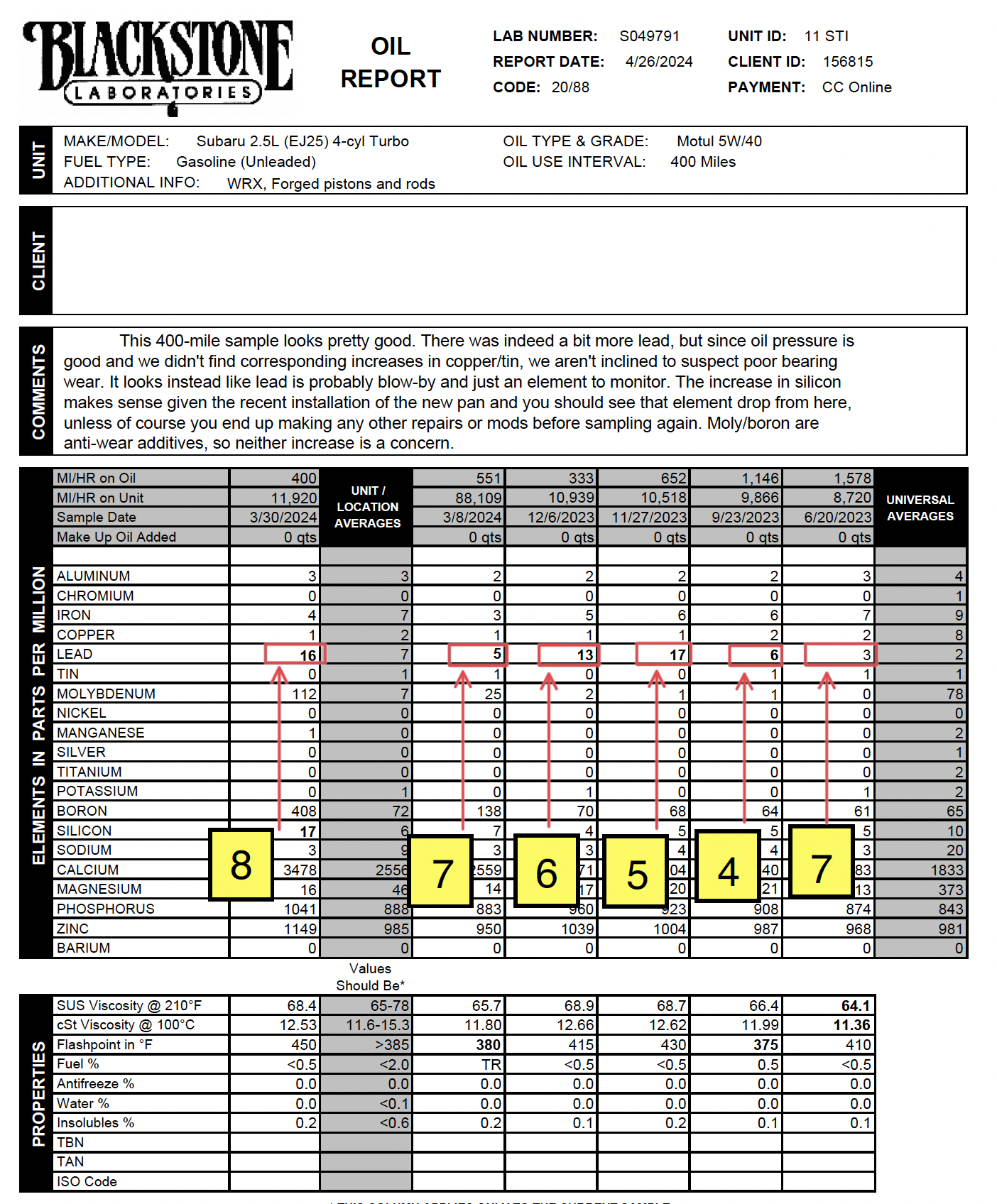

Moving forward, I will have two more data points to work with. I installed an IAG competition oil pan to eliminate oil starvation at the track, which could be the culprit for higher lead levels if it causes accelerated bearing wear. Since my non-100 octane sample didn’t have any track time on it, I can’t completely rule out some accelerated wear from track driving. I also have another cross-country move ahead of me and will drive 2000 miles on pump gas. If this sample shows normal lead levels ( i.e. repeat the results), then I’ll feel high confidence that the source of my elevated lead is exclusively the result of the 100 Octane fuel.

UPDATE!

The post track day sample with the new IAG competition pan came back(#8)! After another track day running 50/50 mix of 93/100 octane, the sample showed a corresponding in lead as expected. Furthermore, with the competition pan installed and video of the oil pressure gauge during laps, oil starvation can be ruled out as a culprit! I’ll have more samples in the future, but at this point I can be confident that the culprit of my elevated lead readings are the result of using 100 Octane unleaded fuel while at the track and not bearing wear!

So How Do You know if You Have a Bearing Problem:

If you have a significant bearing issue, the most obvious symptom will the the noise. Watch some examples on YouTube; if you have a spun bearing, it will likely be obvious.

You may see erratic or low oil pressure. Check with your manufacturer to find out what your engine’s normal operating oil pressures are.

Oil samples are only useful if you do them regularly and compare results over time. Most rod bearings will wear lead first (check with the manufacturer for what metals your bearings contain). As the problem gets worse and the first layer of lead wears away on your bearings, other metals will rise.

Beware of false alarms caused by additives like octane boosters and high octane race fuels.

If the engine is running fine without alarming noises and good oil pressure, then elevated lead is likely something other than excessive bearing wear.

For context on the range of lead levels from concerning to extremely concerning, I found a few examples of oil samples before a rob bearing failure or from vehicles that had confirmed bearing damage. The lead values were 2-5 times as high as my sample with 17 ppm.